Boeing announced on Tuesday its plans to introduce design changes aimed at preventing future mid-air cabin panel blowouts, following an incident on an Alaska Airlines 737 MAX 9 flight in January. This incident resulted in the planemaker facing its second major crisis in recent years.

The National Transportation Safety Board (NTSB) and Boeing have not yet identified who removed and reinstalled the door plug on the plane during production, a critical factor in the blowout. The NTSB conducted the first day of hearings, lasting nearly 10 hours, to investigate the mid-air emergency which caused severe damage to Boeing’s reputation. The incident led to the grounding of the MAX 9 for two weeks, a ban on expanding production by the Federal Aviation Administration (FAA), a criminal investigation, and the departure of several key executives.

Elizabeth Lund, Boeing’s senior vice president for quality, stated during the hearing that the company is working on design changes with the aim of implementing them within a year and subsequently retrofitting the entire fleet to prevent similar incidents. Lund mentioned that the changes would allow the door plug to remain open if any issue arises until it is securely fastened.

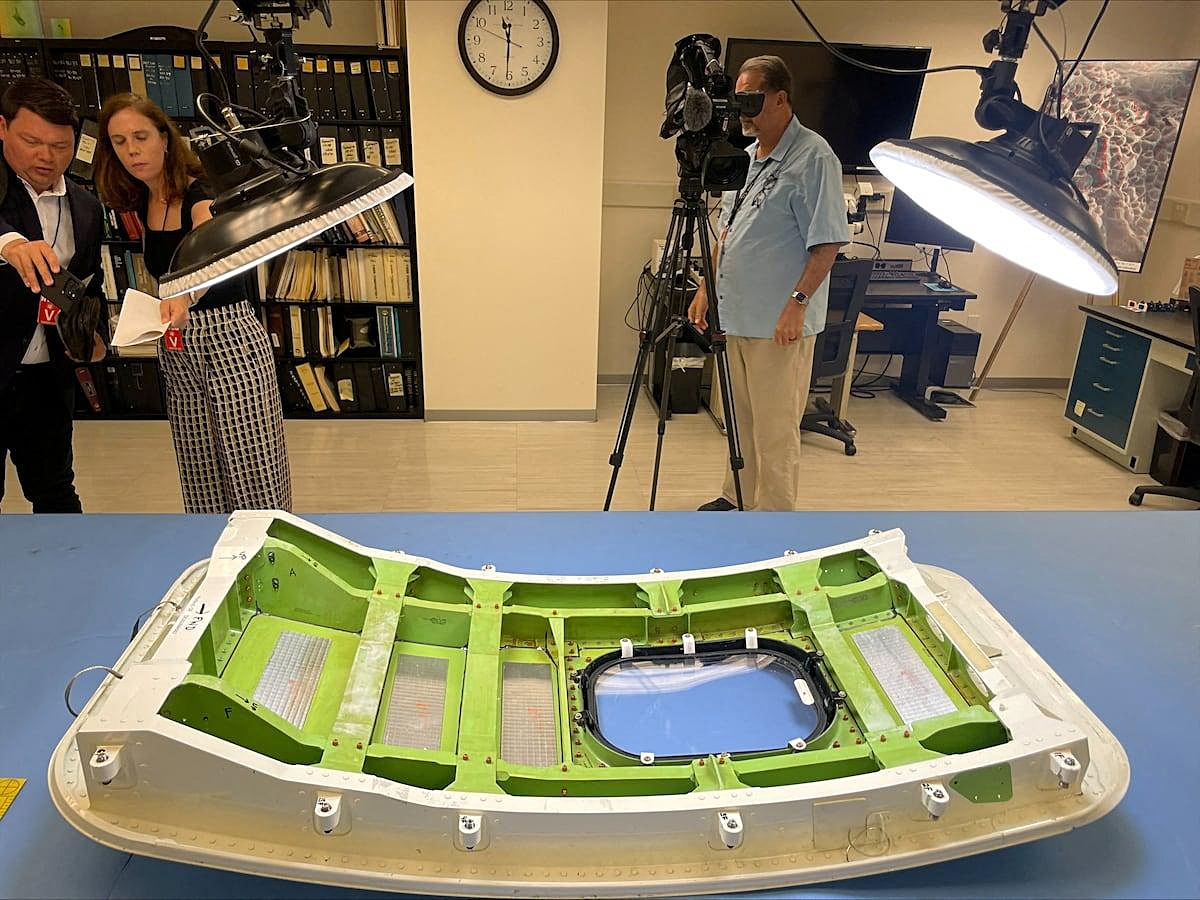

The investigation has revealed that the door plug on the Alaska MAX 9 was missing four crucial bolts. The hearings also address various key issues, such as the manufacturing and inspections of the 737, safety management and quality management systems, FAA oversight, as well as the opening and closing procedures of the door plug.

Boeing, which has pledged to make significant quality improvements, faced extensive questioning at the hearing regarding the production of the accident-hit MAX 9 and the lack of documentation regarding the removal of the door plug.

NTSB Chair Jennifer Homendy criticized Boeing’s safety practices during the hearing and called for necessary improvements to their safety culture. Homendy highlighted the need for more effective oversight by the FAA, which will be the focus of the NTSB’s attention on the second day of hearings. FAA Administrator Mike Whitaker previously admitted that the agency had been too hands-off in its oversight of Boeing prior to the accident.

Lund confirmed that two Boeing employees, who were likely involved in opening the door plug on the 737 MAX 9 during production, have been placed on paid administrative leave. Additionally, the NTSB released 3,800 pages of factual reports and interviews pertaining to the ongoing investigation.

Boeing stated that there is no existing paperwork documenting the removal of the four missing bolts. Consequently, the company has implemented measures such as attaching a bright blue and yellow sign to the door plug upon arrival at the factory, indicating that it should not be opened. Specific requirements and procedures have also been established in case the door plug needs to be opened, ensuring it is not inadvertently opened during the production process.

An interview with a flight attendant who experienced the blowout described the incident as a moment of terror, with a loud bang and a rush of air. The attendant witnessed masks dropping down and observed the galley curtain being sucked toward the cabin.

Doug Ackerman, vice president of supplier quality for Boeing, stated that the company works with approximately 1,200 active suppliers for its commercial airplanes, supported by 200 supplier quality auditors.

Lund also disclosed that Boeing’s monthly production of the MAX aircraft remains low, currently in the 20s, compared to the 38 per month that is allowed. She assured the NTSB that Boeing is gradually increasing its production capacity, having reached a low point of eight MAX aircraft per month. Furthermore, Boeing recently agreed to purchase Spirit AeroSystems, a former subsidiary whose plants were spun off in 2005, for $4.7 billion in stock.

Arnold, an aviation mechanic, commented on Boeing’s tendency to deviate from instructions and identified tool control as a common issue. Lund acknowledged that every 737 fuselage delivered to Boeing by Spirit AeroSystems before the accident on January 5 had defects. She highlighted the company’s determination to avoid significant defects that could disrupt the production system.

Carole Murray, a Boeing executive, mentioned several problems encountered with Spirit AeroSystems’ fuselages leading up to the accident. These included defects related to sealant, multiple escapements around the window frame, and skin defects.

Michelle Delgado, a structures mechanic who worked as a contractor at Boeing and performed rework on the Alaska MAX 9 aircraft, expressed the heavy workload and long hours required to ensure safety and prevent potential issues.

In June, the NTSB stated that Boeing violated investigation rules when Elizabeth Lund provided non-public information to the media and speculated about possible causes of the accidents. Last month, Boeing agreed to plead guilty to a criminal fraud conspiracy charge and pay a fine of at least $243.6 million as part of a settlement with the Justice Department regarding two fatal 737 MAX crashes.

Discover more from Tension News

Subscribe to get the latest posts sent to your email.